Outbound Shipments

Outbound Shipments can be used to issue stock to a customer.

If you have used mSupply in the past, you may be familiar with the term Customer Invoice instead of Outbound Shipment. An Outbound Shipment can be used to:

- Transfer stock to another store which also uses mSupply

- Issue stock to a customer

- Fulfill requisitions (customer orders)

Viewing Outbound Shipments🔗

Open the Outbound Shipments Menu🔗

Choose Distribution > Outbound Shipment in the navigation panel.

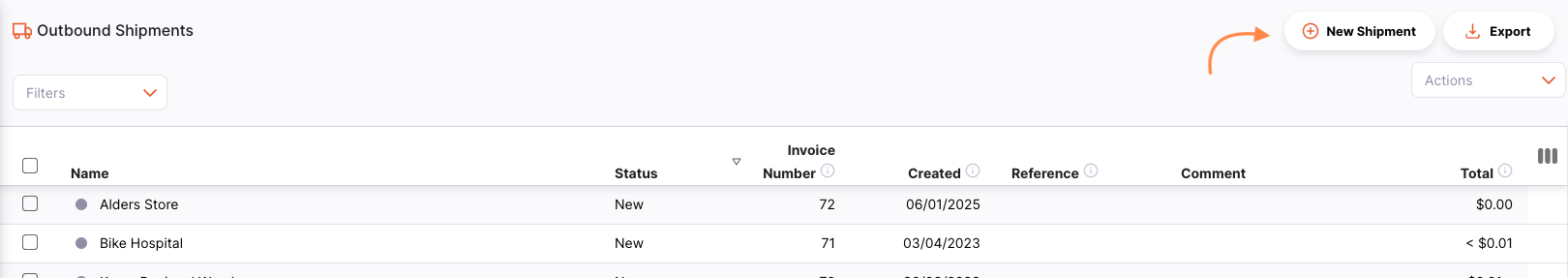

You will be presented with a list of Outbound Shipments (if you don't see any, you are probably just starting!).

From this screen you can:

- View a list of Outbound Shipments

- Create a new Outbound Shipment

- Export Outbound Shipments to a

.csvfile - Print one or multiple Outbound Shipments

Outbound Shipment list🔗

- The list of Outbound Shipments is divided into 7 columns:

| Column | Description |

|---|---|

| Name | Name of the Customer |

| Status | Current Status of the shipment |

| Number | Reference Number of the shipment |

| Created | Creation date of the shipment |

| Reference | Customer reference |

| Comment | Comment for the shipment |

| Total | Total value of the shipment |

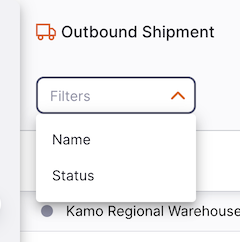

Search by Name or Status🔗

You can filter the list of shipments by customer name or by status. This can be useful if you're looking for one particular shipment!

Select the Name filter from the list to filter by the customer name:

Type the name of a customer in the Name field. All the shipments for this customer will appear in the list.

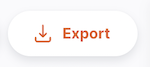

Exporting Outbound Shipments🔗

The list of Outbound Shipments can be exported to a comma separated file (csv). Simply click the export button (on the right, at the top of the page)

and the file will be downloaded. The export function will download all Outbound Shipments, not just the current page, if you have more than 20 of them.

Delete an Outbound Shipment🔗

You can delete a shipment from the Outbound Shipment list.

-

Select the shipment that you want to delete by checking the box on the left end of the list. You can select more than one shipment to be deleted. You can even select them all using the master checkbox in the list headers.

-

The

Actionsfooter will display at the bottom of the screen when a shipment is selected. It will display the number of shipments selected and the actions which can be taken. ClickDelete. -

A notification confirms how many shipments were deleted (bottom left corner).

SHIPPED.

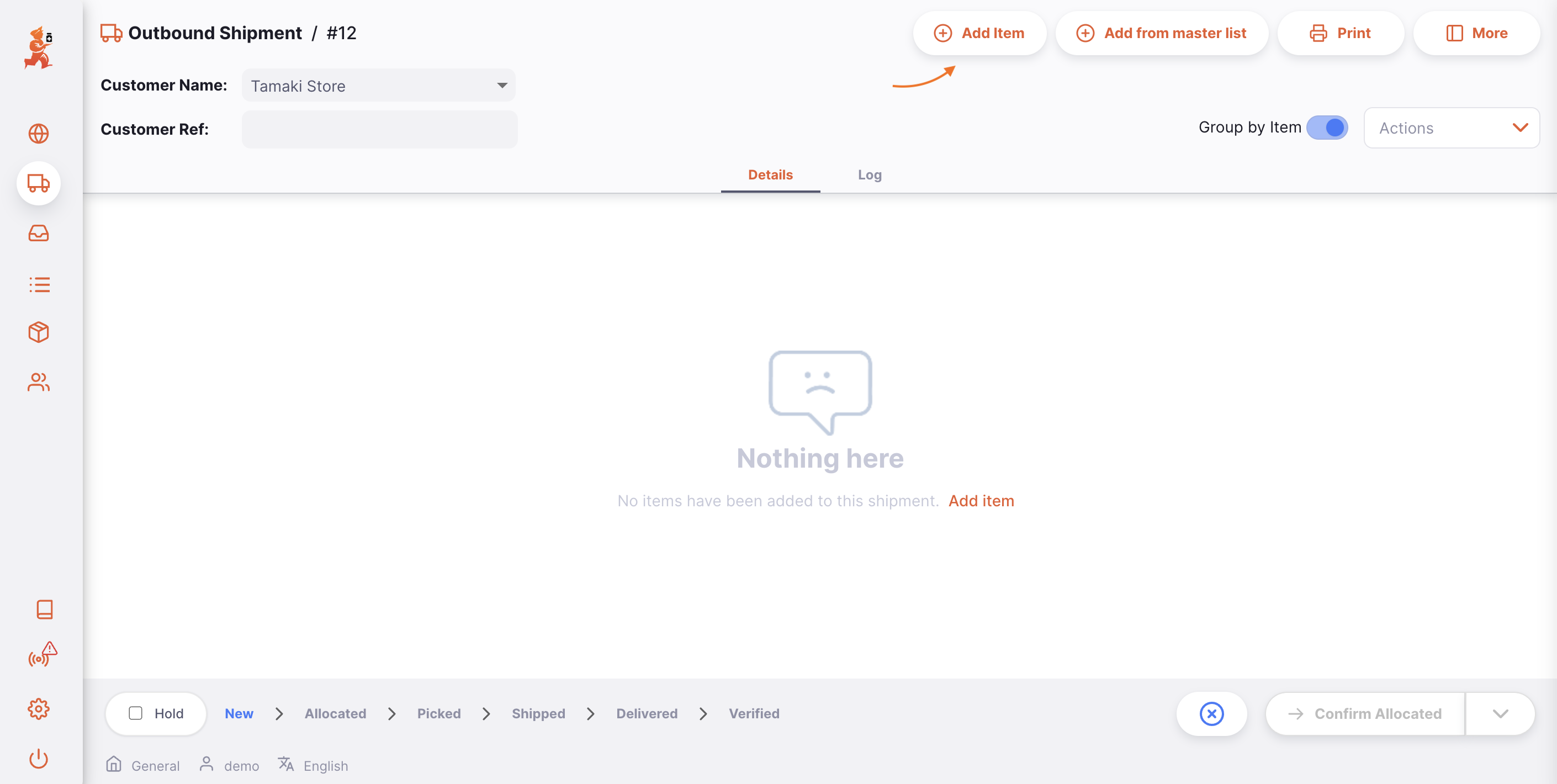

Creating an Outbound Shipment🔗

-

Go to

Distribution>Outbound Shipment. -

Press the

New Shipmentbutton, in the top right corner

- A new window

Customersopens, inviting you to select a customer.

Select a Customer🔗

- In the

Customerswindow, you will be presented with a list of available customers. You can select your customer from the list or you can type as much of a customer name.

- Once you tap or press

Enter, or click on a customer, your Outbound Shipment is automatically created

NEW

Edit the Customer Name🔗

If you have selected the wrong customer, you can change the customer name in the Customer Name field or select one the dropdown list:

Enter a Customer Reference🔗

Once your Outbound Shipment has been created, you can enter a customer reference in the Customer Ref field, if they have one (eg. PO#1234567)

View or edit the Outbound Shipment Information Panel🔗

The Information Panel allows you to see or edit information about the Outbound Shipment. It is divided into multiple sections:

- Additional Info

- Related Documents

- Invoice Details

- Transport Details

We are planning to add more sections in the future as Open mSupply grows.

How to open and close the Information Panel?🔗

If you are using a large screen, the information panel will be automatically opened for you. However, on an average sized screen, the information panel will be closed by default.

To open the Information Panel, you can tap on the More button, located in the top right corner of the Outbound Shipment view.

You can close by tapping on the X Close button, on the top right corner of the information panel.

Additional Info🔗

In the Additional Info section, you can:

- See who created the Outbound Shipment (name of the user)

- View and edit the Outbound Shipment color. To edit the color, tap on the colored circle and select a color from the pop-up

- Write or edit a comment

Related Documents🔗

In the Related Documents section, you can see other related transaction document for the Outbound Shipment.

If your Outbound Shipment was created to fulfill a Requisition, the reference number of the requisition would appear in this section.

In the future, we would also include other documents such as temperature records, transportation documents or pick slips.

Invoice Details🔗

In this section, you will see by default the total selling price of the items listed in the Outbound Shipment.

You can also add service charges if you wish to add other charges such as Freight Costs.

To add a service charges to the Invoice Details:

- Tap on the three dots besides

Service chargesto get a new window to appear. - Tap on the

Add chargebutton on the new window. A new line appears in the list of charges. Tap onCancelif you do not wish to add anything - Name: Select a service charge from the dropdown list. You can customise the list of available charges. Contact your administrator

- Comment: You can add a comment to provide further details about the new charge

- Amount: Enter the amount of the charge

- Tax: Enter a % of tax for the charge

- Total: The total field is automatically calculated based on the amount and the tax percentage

- Delete: You can tap on the

Deleteicon to delete the charge

The tax rate (%) for service charges and the item's sell price can also be edited by clicking on the pencil icon. A pop-up window will appear for you to enter a value.

Foreign Currencies🔗

If your store is issuing in foreign currencies follow these instructions in the central server documentation to set it up. You will also need to enable the store preference Store: Able to issue in foreign currency. This preference is compatible with Open mSupply v1.7.0+.

The pen icon will become active once the above instructions have been followed and only if the customer is an external customer. Click on this icon and change to a currency that you would like to issue the shipment in. The currency rate can also be edited if you and the customer have agreed on a different rate.

You can also see the foreign currency totals in the invoice line details as well.

You can also see the foreign currency totals in the invoice line details as well.

Transport Details🔗

In this section, you can see or edit a transport reference number (eg. a booking or a tracking reference number).

Actions🔗

- Delete: You can tap on the

Deletebutton to delete the invoice - Copy to Clipboard: You can tap on the

Copy to Clipboardbutton to copy the invoice details to the clipboard.

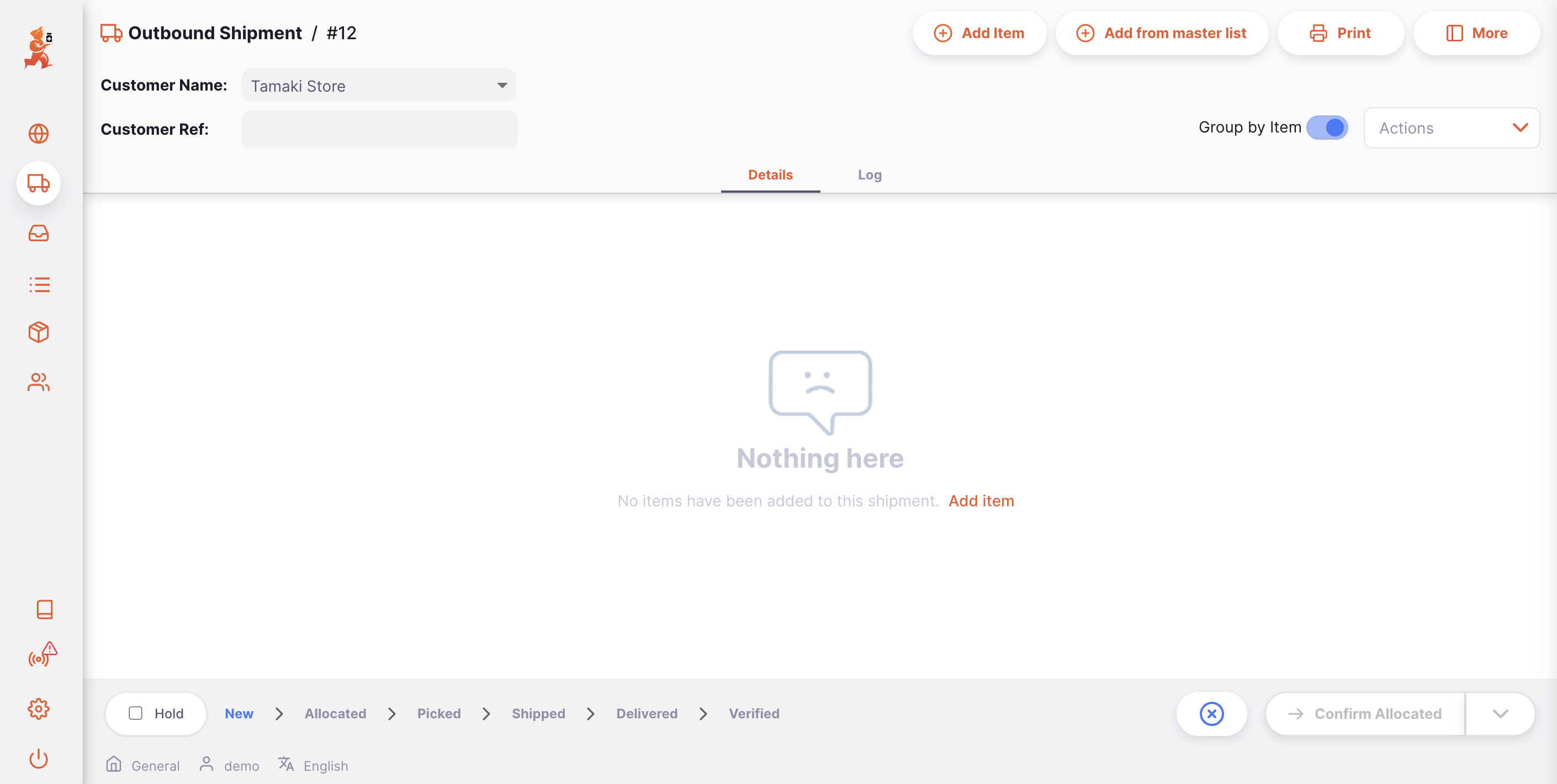

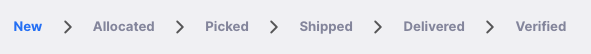

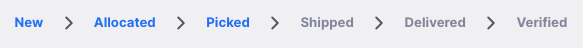

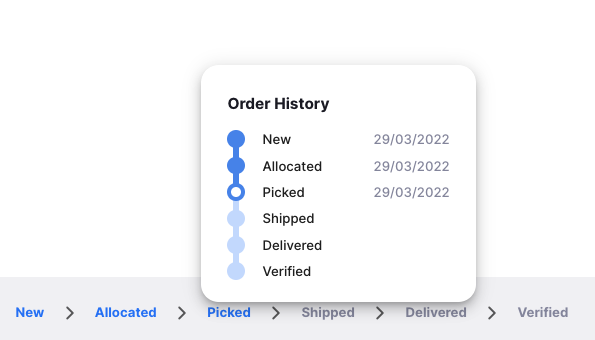

Outbound Shipment Status Sequence🔗

The status sequence is located at the bottom left corner of the Outbound Shipment screen.

Passed statuses are highlighted in blue, next statuses appear in grey.

There are 6 status for the Outbound Shipment, these are listed below alongside the comparable status in mSupply

| Status | Description | mSupply | Editable |

|---|---|---|---|

| New | This is the first status when you create a shipment | sg | ✓ |

| Allocated | Allocation is confirmed. Goods are no longer available for other shipments but are still part of your inventory | sg | ✓ |

| Picked | Shipment is picked and is now ready to ship. Goods are no longer part of your inventory | cn | ✓ |

| Shipped | Shipment has been shipped. | fn | |

| Delivered | Your customer has received the shipment. Goods are now part of their inventory | fn | |

| Verified | Your customer has verified the quantity of the shipment. | fn |

If you hover over the status sequence, a shipment history window appears. You can see the date when a shipment was updated from one status to another.

Hold checkbox🔗

Located on the bottom left corner, on the left of the status sequence.

Checking the Hold checkbox prevents the Outbound Shipment from being updated to the next status.

Cancel and Confirm button🔗

Cancel Button🔗

Tap on the Close button to quit the Outbound Shipment view and return to the Outbound Shipments list.

Confirm Button🔗

The Confirm button updates the status of a shipment. The status which you can confirm depends on the current status of the shipment and follows the sequence shown below.

When managing an Outbound Shipment, you can only confirm the Allocation, Picked and Shipped statuses.

| Confirm... | Current Status | Next Status |

|---|---|---|

| Confirm Allocated | New | Allocated |

| Confirm Picked | Allocated | Picked |

| Confirm Shipped | Picked | Shipped |

You don't have to update a shipment to the next status in the sequence. You can choose to skip some of them to go directly to Confirm Shipped for example.

As demonstrated below, tap on the down arrow of the Confirm button and select the status you want the shipment to be updated to.

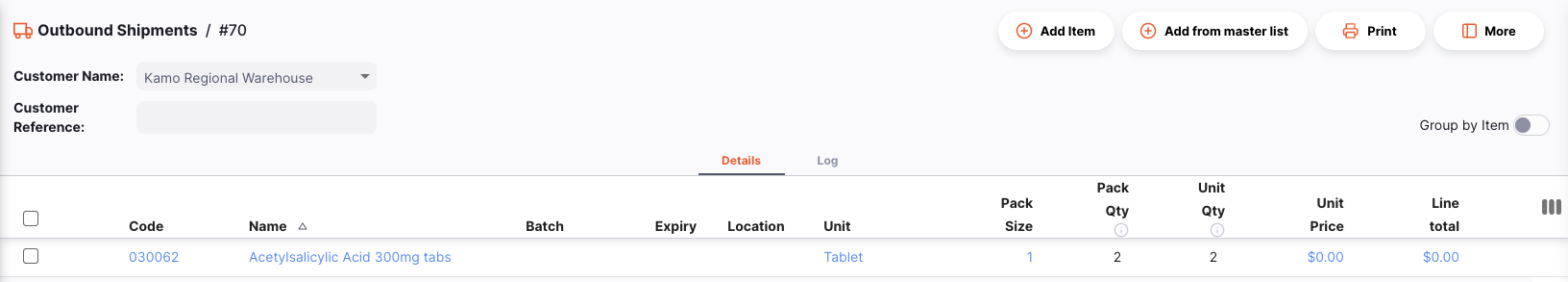

Adding lines to an Outbound Shipment🔗

Tap on the Add Item button (top right corner).

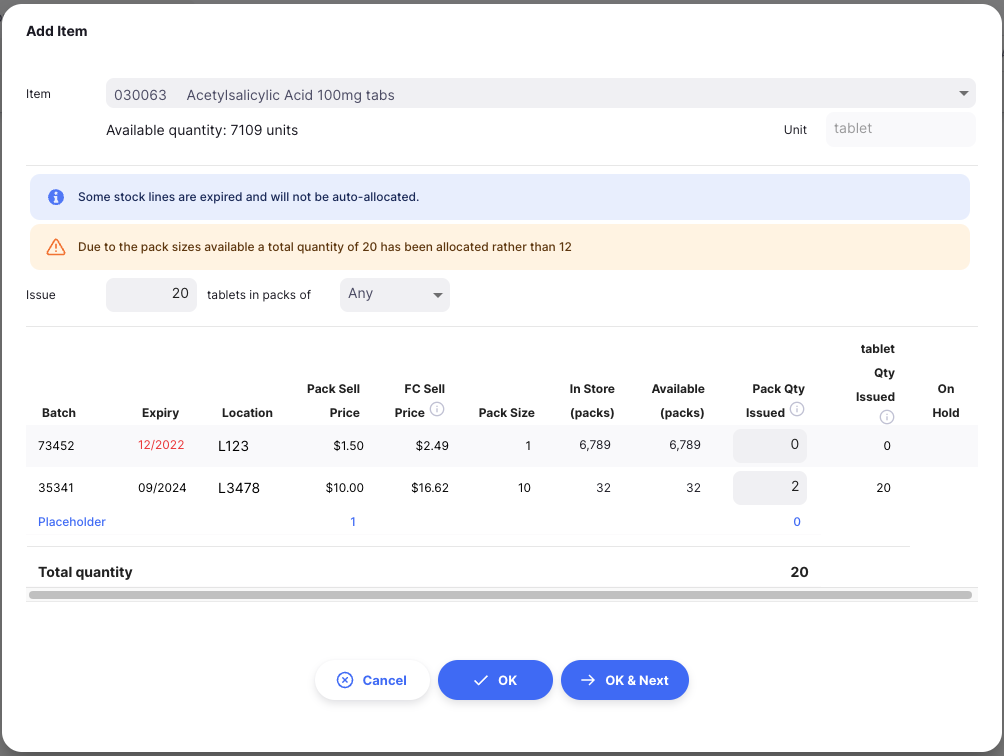

A new Add Item window opens.

Adding using a barcode scanner🔗

For another way to add items, if you are using the desktop client or android app, you can make use of barcode scanning to add items.

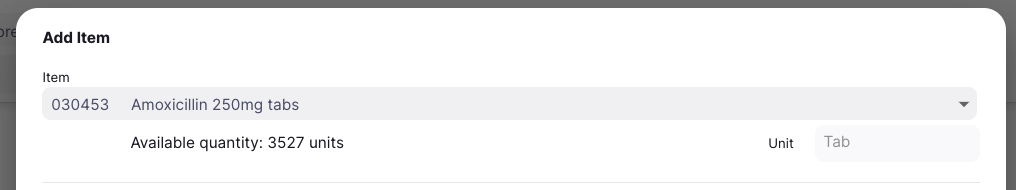

Select an Item🔗

In the Add Item window, you can look up an item by:

- Reading through the list of available items

- or by typing some or all of the item name

- or by typing some or all of an item code

Once your item is highlighted, tap on the name or press Enter.

Once the item is selected, you can see the following information:

Headers🔗

- Item code and name (eg. 030453 Amoxicillin 250 mg Tabs)

- the available stock quantity for this item (eg. 3527 units)

- the item's unit (eg. Tab)

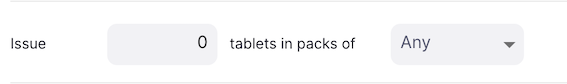

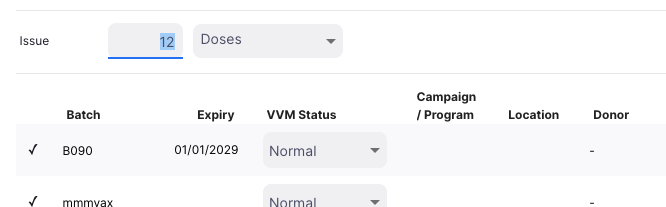

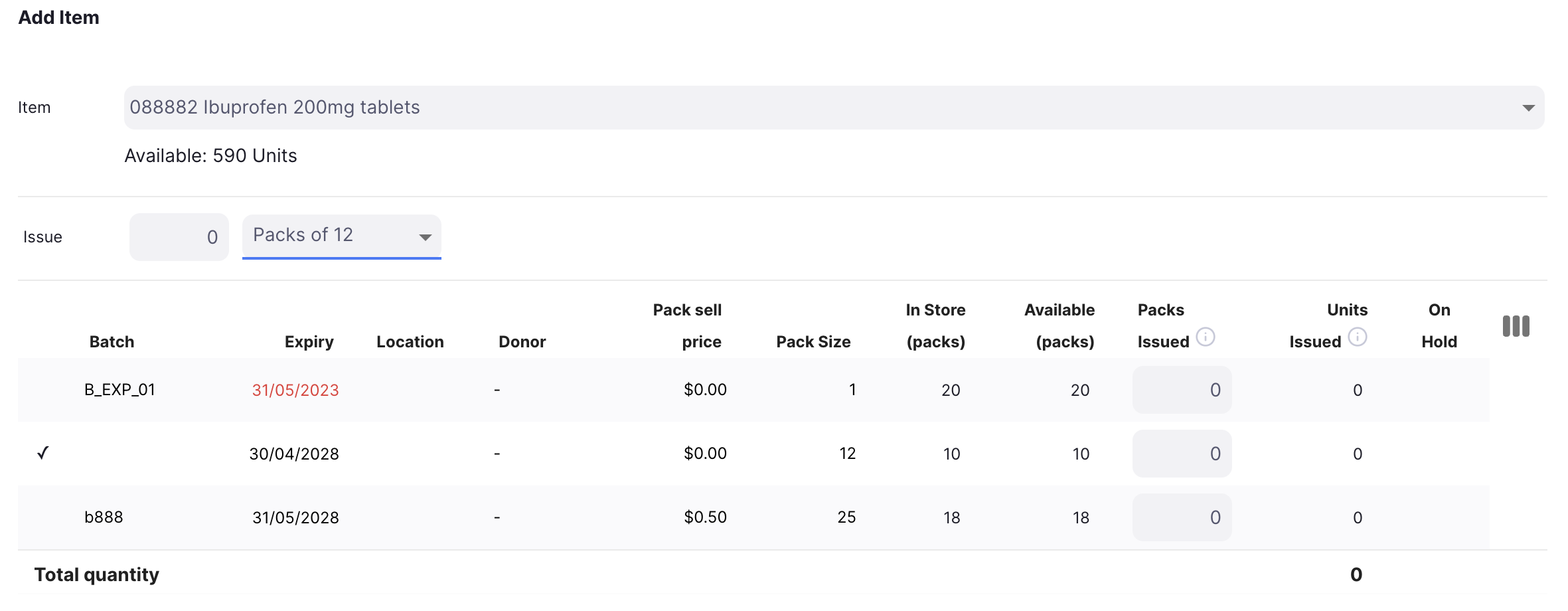

Issue [Quantity] of units in packs of [Pack Size]🔗

In the Issue field, you can enter the quantity that you want to issue to your customer.

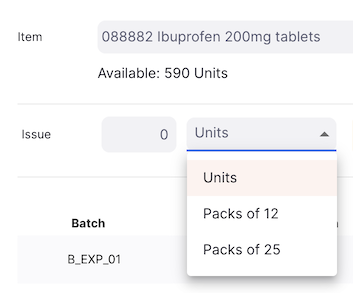

By default, you are invited to issue a quantity of units. However, you have the possibility to issue a quantity of packs instead by changing the value in the second dropdown (Pack Size).

Default value is Any when you are issuing units.

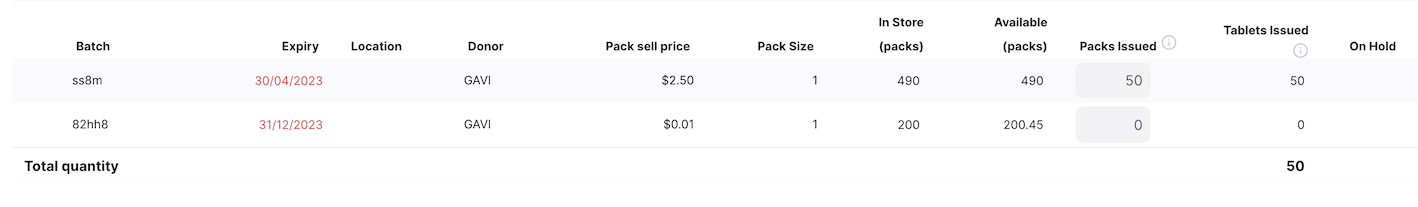

List of available batches:🔗

This is a list of batch numbers that you have in store for this item:

| Column | Description |

|---|---|

| Batch | Batch number. It is a designation given to products made in the same manufacturing run. |

| Expiry | Expiry date of the batch (format: MM/YYYY). Note: the date shows in red if the expiry is within the next 3 months. |

| Campaign | Shows the name of the campaign which this stock line is associated with, if any. The columns will only be shown if some campaigns are configured. See Campaigns for configuration details. |

| Location | This is the code of the location where the item is stored if your inventory is managed with storage locations |

| Donor | Only shown if the Global preference for Allow tracking of stock by donor is enabled. This shows the name of the donor linked to the stock line if there is one. |

| Pack Sell Price | Selling unit price of the item |

| Pack Size | Quantity of units per pack |

| In Store (packs) | Total number of packs in your store |

| Available (packs) | Number of packs available (not already allocated to other shipments) |

| [Pack]s Issued | Total number of packs to be issued |

| [Unit]s Issued | Number of units to be issued |

| On Hold | Indicates whether a batch is on hold or not. You cannot issue a batch that is on hold. |

There is also a final row in the table which is a placeholder line, if the status of the Outbound Shipment is NEW.

The placeholder line is used when the quantity you are issuing is higher than your available stock.

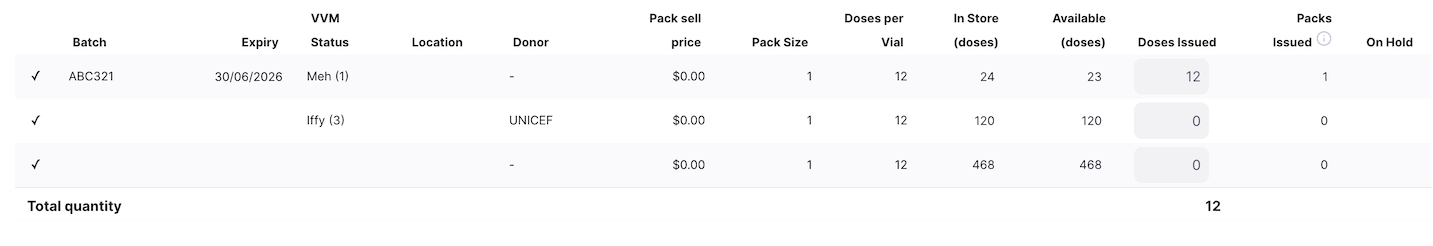

You can issue Vaccine Items in doses when the Display vaccines in doses store preference is turned on. If this is enabled, the following quantity columns will be displayed instead when issuing a vaccine item:

| Column | Description |

|---|---|

| Doses per [unit] | The number of doses per unit |

| In Store (doses) | Total number of doses which are in stock at your store |

| Available (doses) | Total number of doses available for issuing (some may be allocated to other shipments and not yet shipped from the store) |

| Doses Issued | Total number of doses to be issued |

When the Manage VVM status for stock store preference is turned on you will be able to edit the VVM status of a stock line directly:

Issue a quantity of units🔗

By default, you are invited to issue a quantity of units, regardless of the pack size (number of units in a pack).

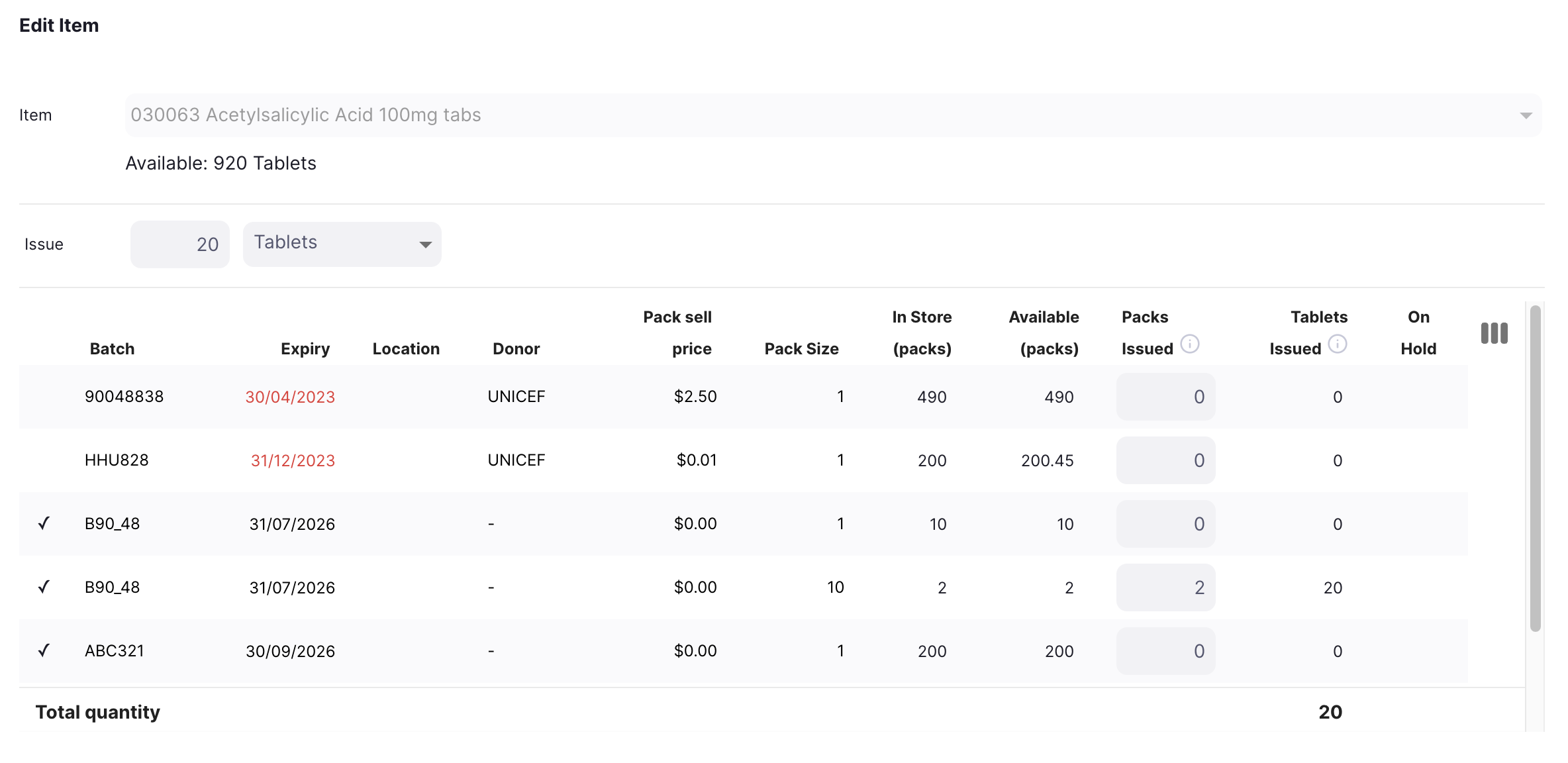

When entering a number in the Issue field, the system automatically chooses the batch number(s) with the closest expiry date (First to Expire, First Out or FEFO logic).

In this case the stock lines are allocated in numerical order of the VVM status 'Level' property (this is separate to the VVM stage, see the documentation for details). If there is more than one line with the same VVM status level, then of those lines the first line to expiry is selected (normal FEFO rules).

Note that in this list, the batches which are available for selection are shown first and batches which are not (on hold or no stock available) are shown below and in a grey font.

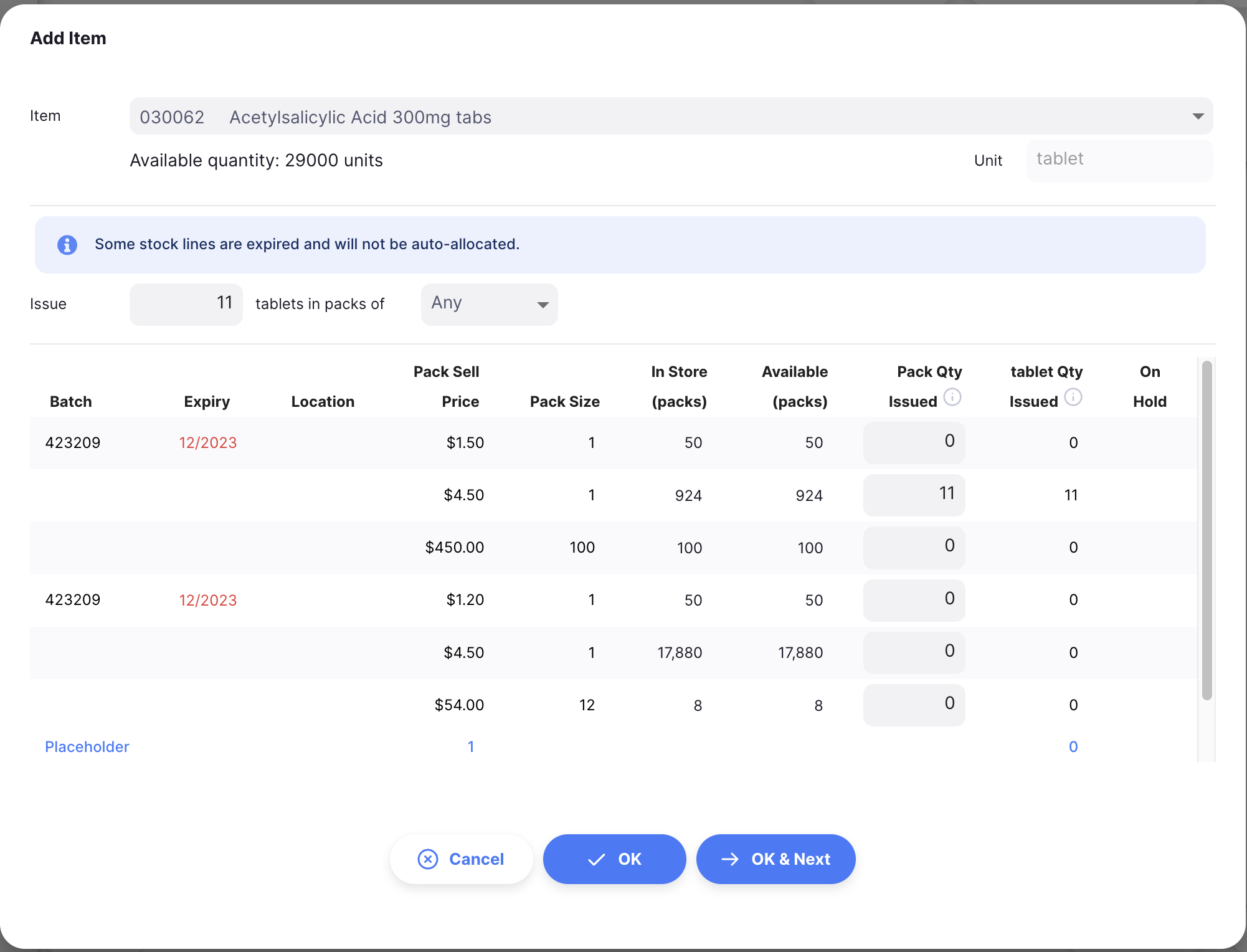

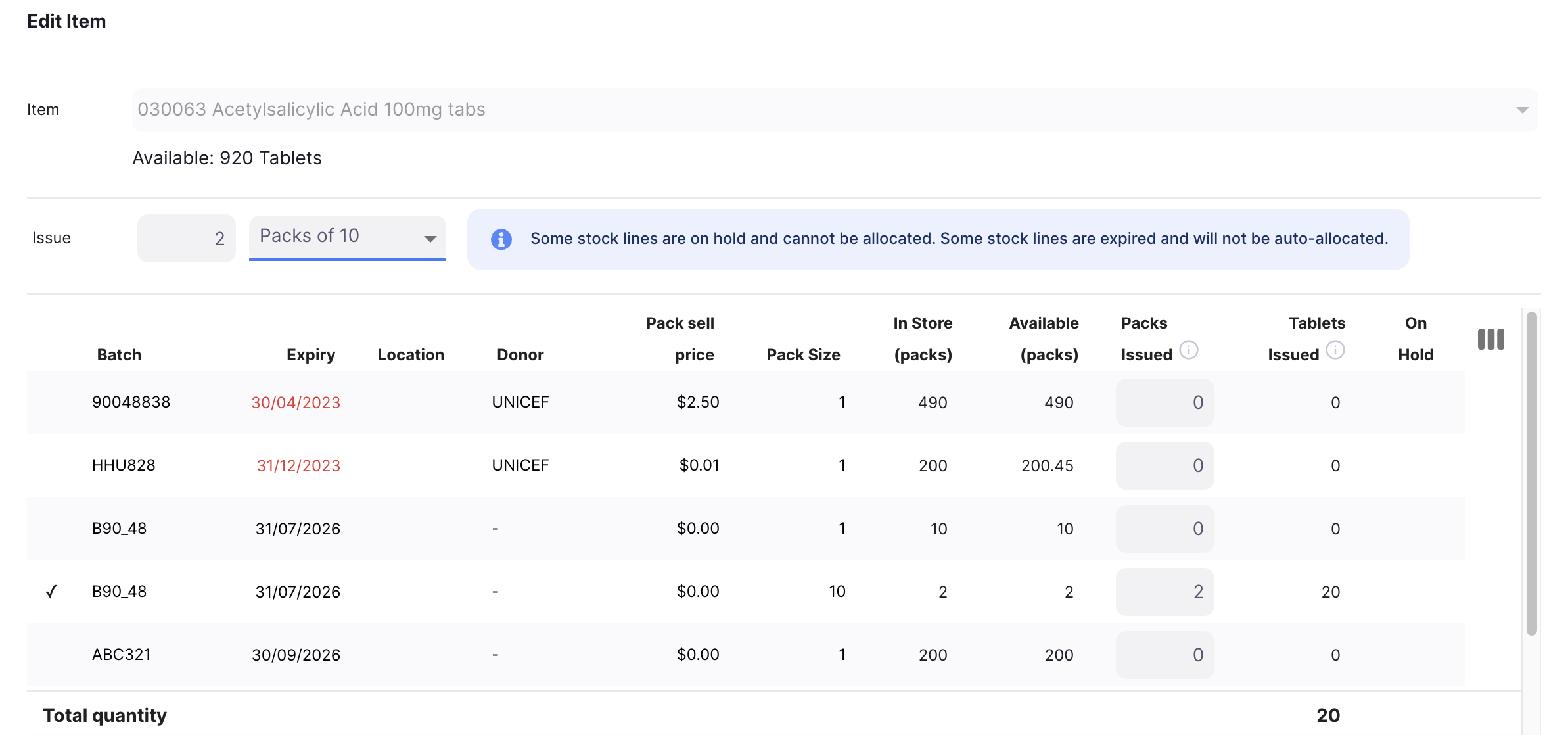

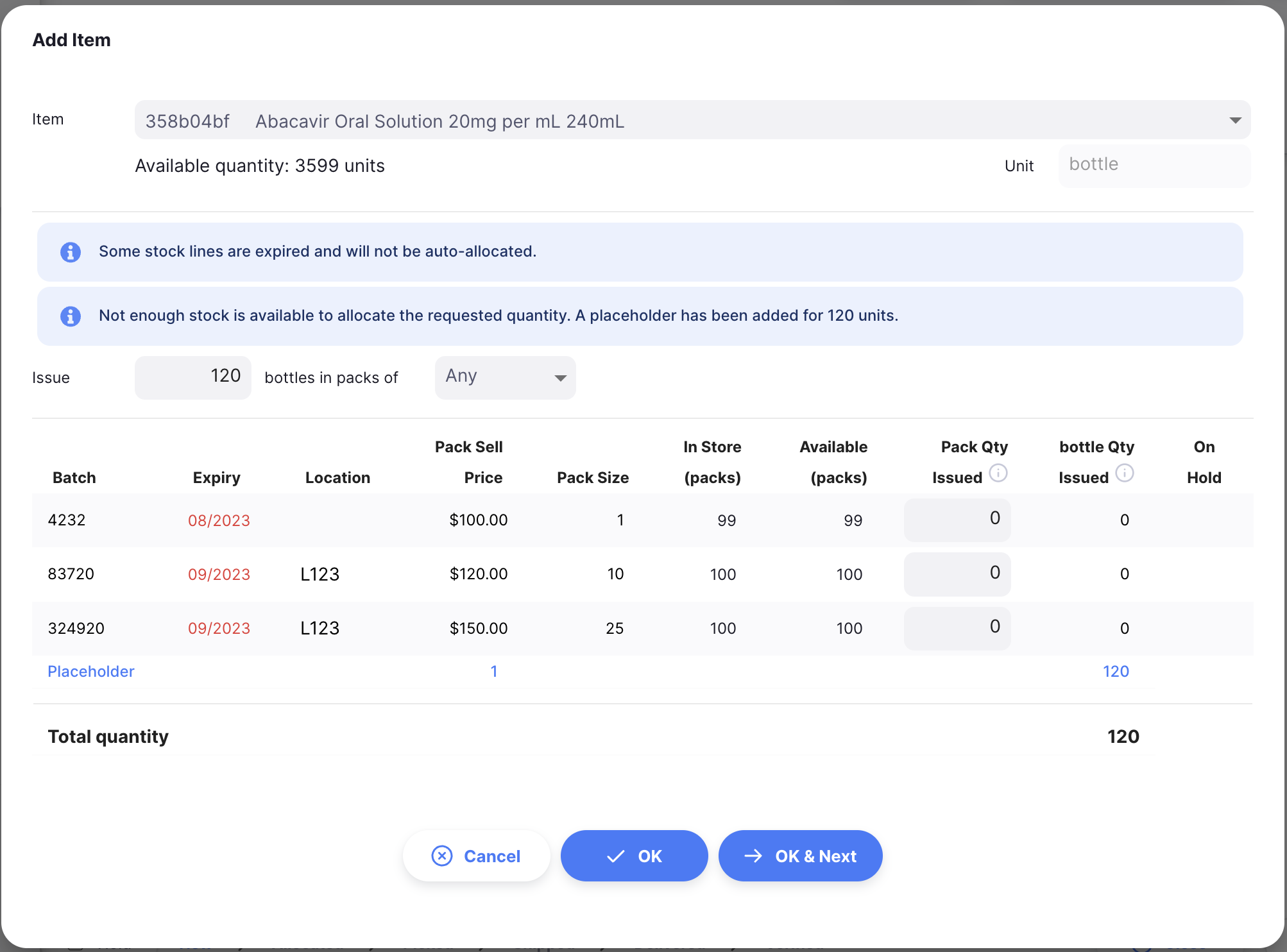

Warnings🔗

You may see one or more warning messages on this screen:

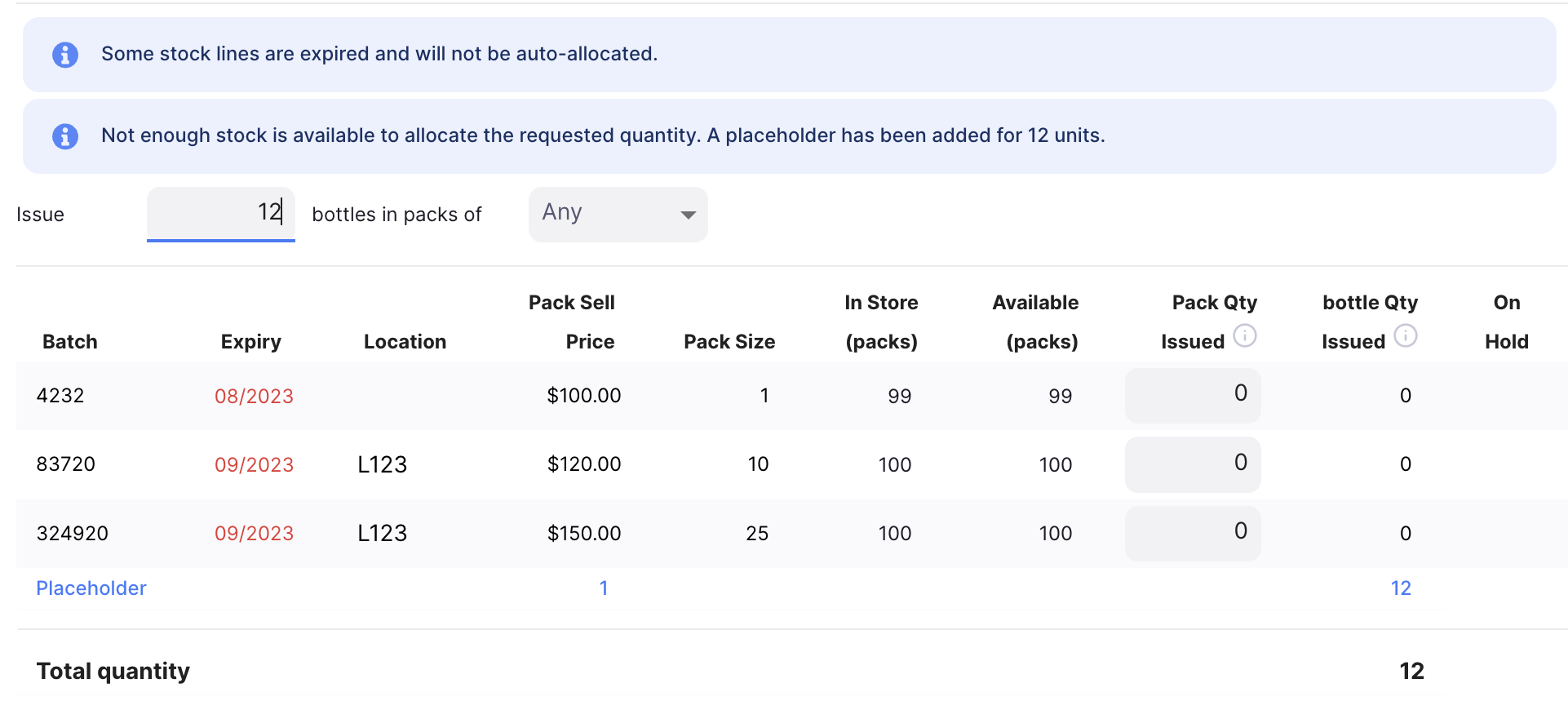

The warning is shown to let you know that not enough stock is available to fulfil your request. A placeholder quantity is added automatically so that you can keep track of the amount requested, while adding more stock (for example by using an internal order or inbound shipment).

This image also shows the warning which lets you know that some stock lines are expired; this may be why the system did not auto-allocate particular stock lines. However you can still manually choose those lines and issue the expired stock!

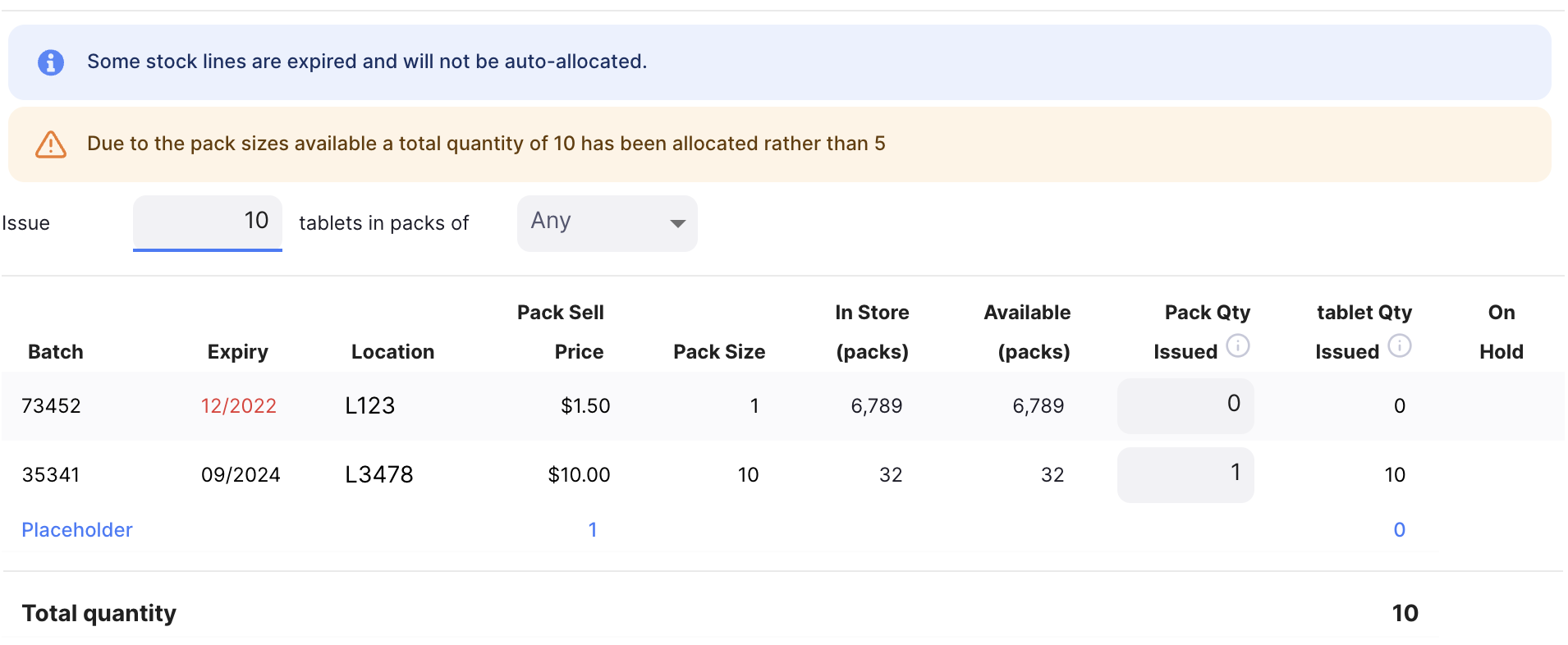

This warning tells you that because of the available pack sizes, the system has rounded up the quantity requested. In this example, there is no pack size that is less than 5. There are packs of 12 available though, so when 3 tablets are requested, the system has rounded up the request to 1 pack of 12.

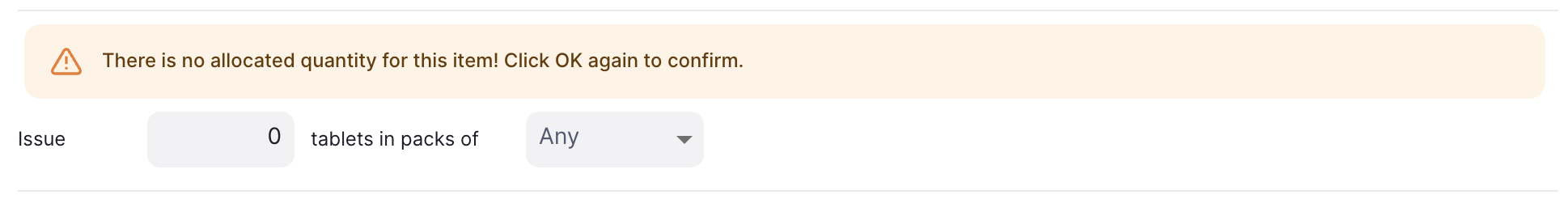

If you add an item, forget to enter a quantity to issue, and click OK you will see this warning message. It is informing you that there is no issue quantity; from here you can click OK again to confirm that you intended to enter 0, in which case the window will close and a placeholder row will be added to the shipment. You can edit the row later and add a quantity. If you forget to add a quantity however, and confirm the shipment as allocated, this row will be removed!

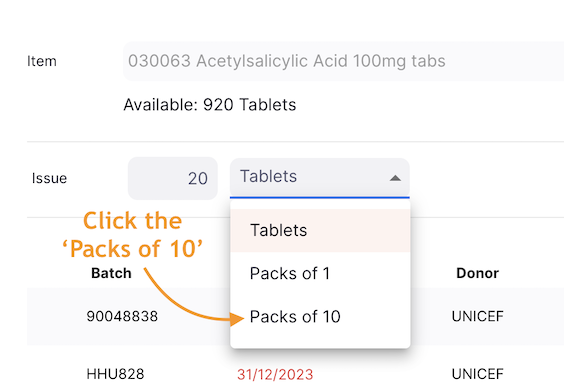

Issue a quantity of packs🔗

You can decide to issue a quantity of packs. To do this, you can change the value in the dropdown.

You are now offered to issue a number of packs of 12 units. Only batch number(s) with a pack size of 12 units will be automatically issued. You can see that the check mark in the first column has changed to indicate which rows are to be automatically allocated ( you can however still manually request a number of packs for the other rows if you need to! ).

Then change to packs

Which changes the Issue value while keeping the total quantity:

When a pack size is selected, stock lines which have a different pack size from the one selected are not automatically allocated.

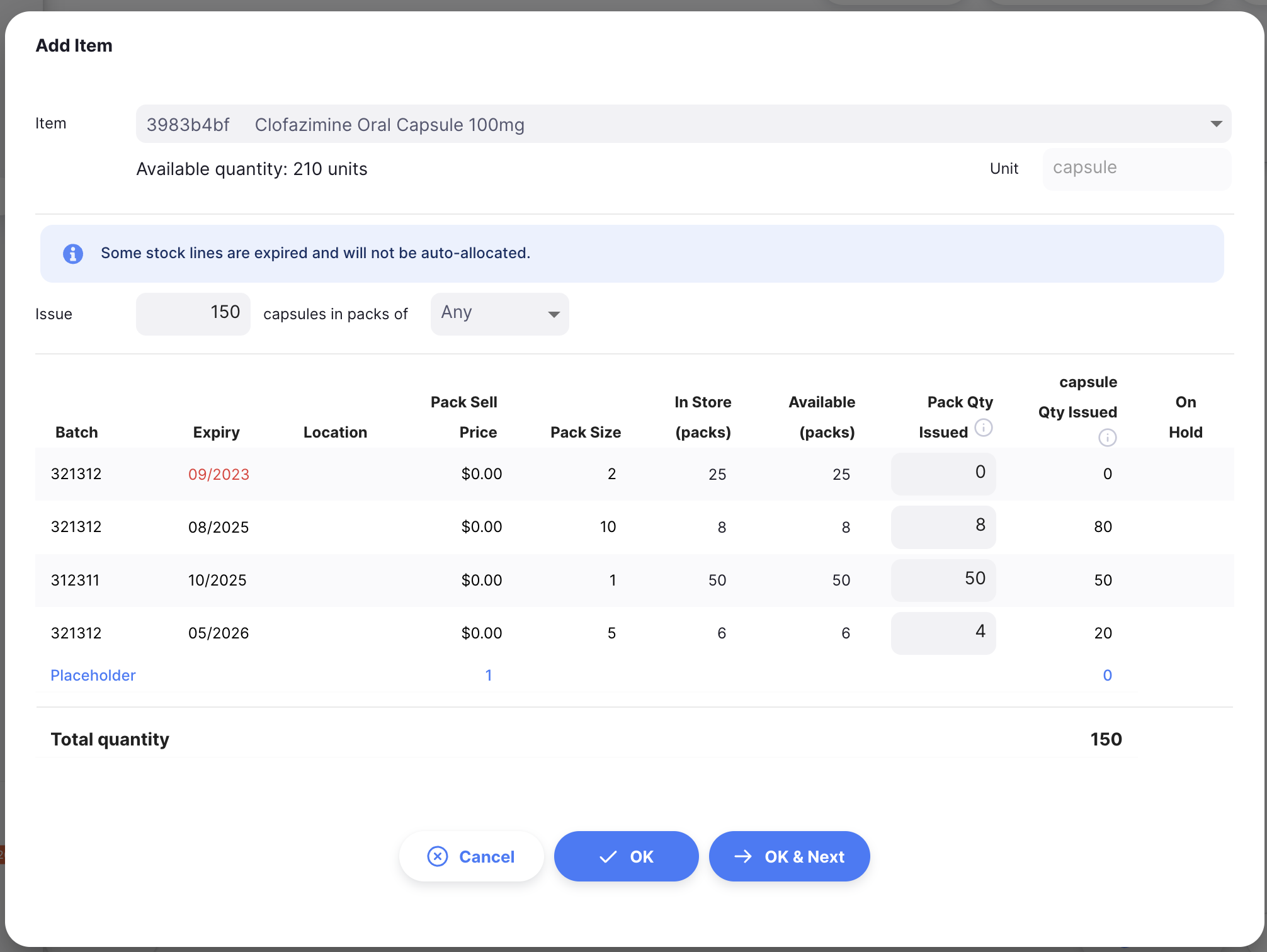

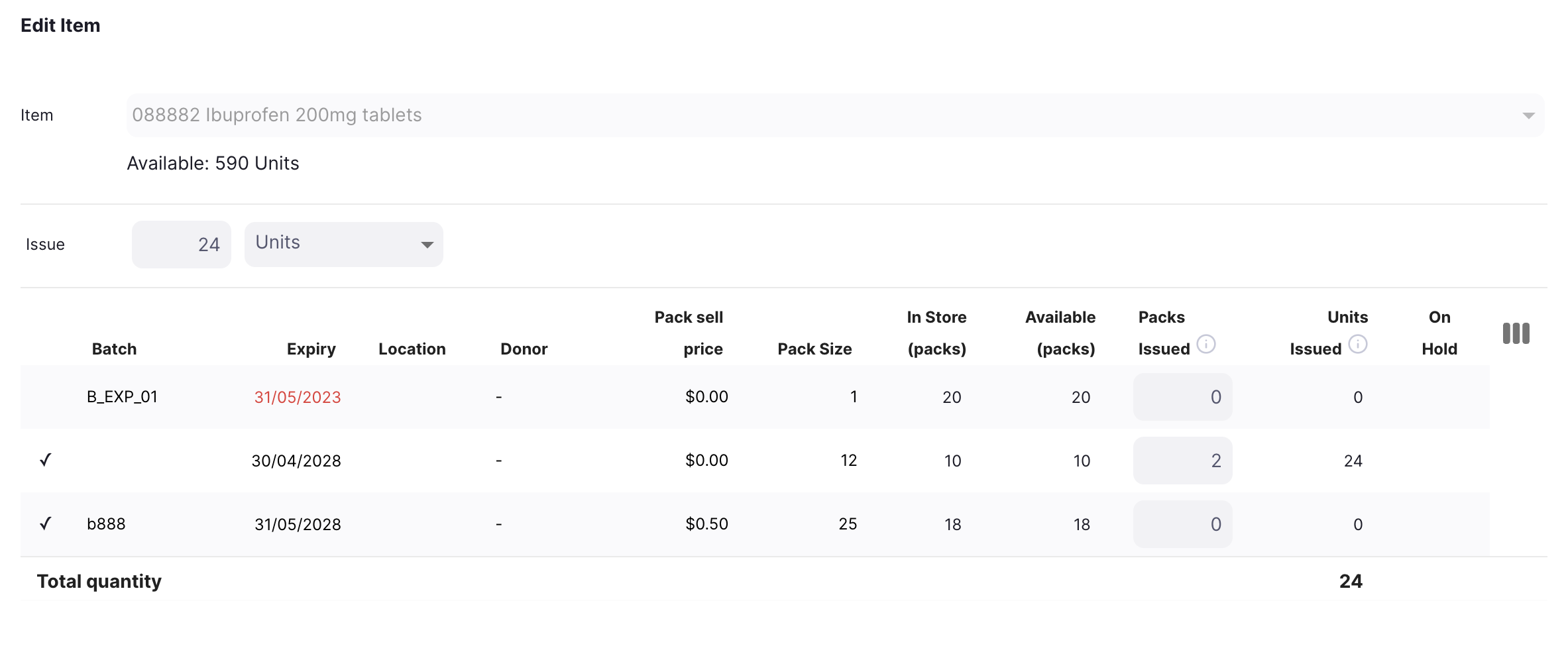

Manual Allocation🔗

Regardless of if you chose to issue a quantity of units or packs, you can always manually change the quantity at the batch number level directly before pressing on OK.

You simply have to enter or edit the quantity in the Packs Issued column.

The values in the Total quantity row will be automatically updated with the new quantity.

Issuing when there is not enough stock (Placeholder Line)🔗

If the amount to be issued is greater than the total stock available from all of the available lines, then the quantity to be issued will automatically be placed in the placeholder field, at the bottom of the list of available batch numbers.

Placeholder lines can be allocated later when new stock arrives. However, all shipment lines must be allocated before confirming the allocation.

When you look at an Outbound Shipment, you can see if a shipment line has not been allocated or has been partially allocated when it is highlighted in blue.

Confirm Item and Quantity🔗

When you are happy with the quantity, you can either press on:

- the

OKbutton. You are redirected to the Outbound Shipment view and your item has been added to the list - the

OK & Nextbutton to add another item right away - the

Cancelbutton if you do not want to add the item to the Outbound Shipment any more

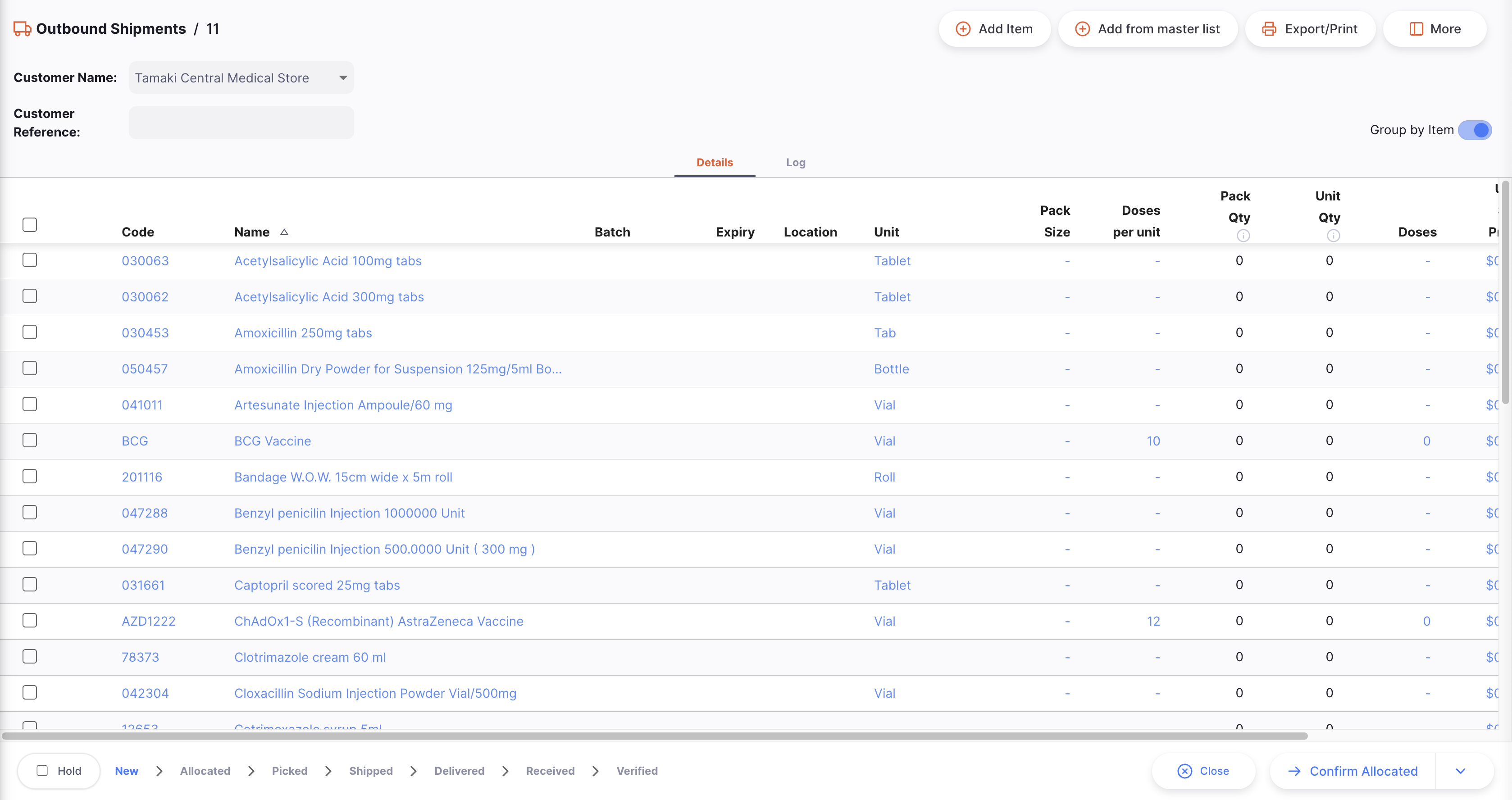

Adding lines to an Outbound Shipment using a Master List🔗

Tap on the Add from master list button (top right corner).

A new Master Lists window opens. This allows you to select the required master list. Simply click on one of the lists (if you have some available).

Note that the lists shown are those which are visible to the customer of the shipment.

Click OK on the prompt:

You will then have unallocated (placeholder) lines added to your shipment, which will then look like this:

As you can see - all of the quantities are zero. You can follow the steps for editing these lines, as detailed above.

Editing an Outbound Shipment Line🔗

To edit a shipment line, tap on it. You will be presented with the Edit Item window, which is identical to the Add Item window, except that the item is already chosen.

Edit a Shipment Line🔗

Shipped.

-

Open the Outbound Shipment you want to edit.

-

Tap on the line you want to edit. An identical window to

Add Itemappears. At this stage:- Edit the main

Issuefield - or change the number of packs value at the batch number level

- Edit the main

Delete a Shipment line🔗

- Open the Outbound Shipment you want to edit.

- Select the line(s) you want to delete by checking the box(es) on the left hand side of the list.

- Click the

Deletebutton which appears at the bottom of the page.

Processing an Outbound Shipment🔗

Allocating an Outbound Shipment🔗

Allocation is the process of assigning one or multiple batch numbers from the inventory to a shipment line. In other words, you are assigning stock to your shipment. Once allocated, the stock is reserved for the shipment and thus for your customer.

There are 2 main ways to allocate a shipment line:

-

When adding items, the system will automatically assign stock to the new shipment line when you enter a quantity. If you don't have enough stock, the system will add placeholder lines (unallocated lines).

-

Bulk action

Allocate placeholder lines: Select the lines that you want to allocate by checking boxes on the left hand side of the list -

Click the

Allocate placeholder linesbutton which appears at the bottom of the page. System will check if there is available stock for each selected line and allocate them using the First to Expire, First Out (FEFO) logic. A notification will let you know whether the operation is successful or not.

Confirming an Outbound Shipment's allocation🔗

Once all your shipments lines have been allocated, you can confirm the allocation:

- Current status of the shipment has to be

NEW - Lines must be assigned with one or several batch numbers. You won't be able to confirm the allocation if your shipment contains lines without batch numbers assigned to it (placeholder lines).

To confirm the allocation, press the Confirm Allocated button.

Once the allocation is confirmed:

- Shipment status is

ALLOCATED - You are now invited to confirm the picking via the

Confirm Pickedbutton - All the items and their quantities will be reserved, meaning that they are no longer available for allocation

- You can print a pick slip to be sent to your warehouse so they can start preparing the shipment

Confirming Outbound Shipment picking🔗

Picking refers to the process where individual items are picked from a fulfilment facility (usually a warehouse or a pharmacy store).

Once a shipment has been allocated, the next step is to go get the items to prepare the actual shipment. To help with that, you are able to generate a pick slip. A pick slip indicates:

- The items to be picked

- The quantity and batch numbers for each item

- If you manage your inventory with storage locations, where the items are located

Once all items are picked and packed. You can then confirm the picking of the shipment to indicate that it is ready to be dispatched. Goods are no longer part of your inventory and cannot be allocated to other shipments once the status has been changed to PICKED.

To confirm that a shipment has been picked, tap on the Confirm Picked button.

Once picking is confirmed:

- Shipment status is now

PICKED - You are now invited to confirm the shipping via the

Confirm Shippedbutton - If your customer is also using mSupply, then an Inbound Shipment has been generated and is now visible to your customer

At this stage, you are still able to edit shipment lines, to add items or to delete existing lines. However, if picking has been confirmed, you need to make sure to inform your fulfilment facility of any change so they can make sure that the shipment is still correct.

Confirming the Outbound Shipment shipping🔗

The last step to issue stock with an Outbound Shipment is to confirm that stock has been shipped. This is a critical step because when goods are confirmed as shipped, they are no longer a part of your inventory records.

To confirm that an Outbound Shipment has been shipped, tap on the Confirm Shipped button.

Once shipping has been confirmed:

- Shipment status is now

SHIPPED - Goods are no longer part of your inventory

- You can no longer edit shipment lines

- You can no longer delete the shipment

- You can print a delivery note or an invoice

Tracking the Progress of Outbound Shipments🔗

If your customer is also using mSupply, you will be able to see when they'll receive your shipments:

- status will become

DELIVEREDwhen goods are received: your customer confirmed that they received your goods - status will become

VERIFIEDwhen shipment has been verified by your customer. Goods are now a part of their inventory.

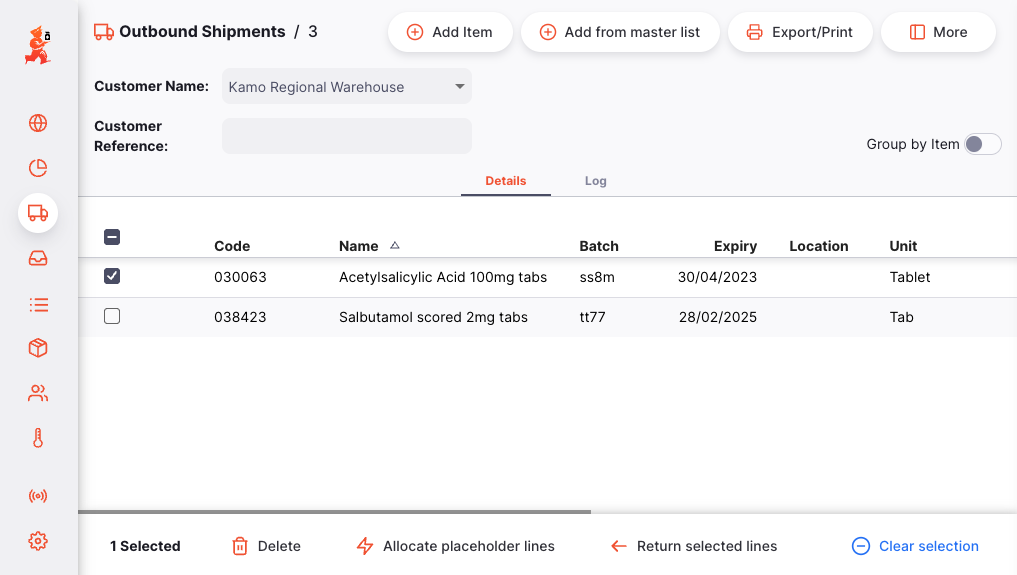

Process return of stock from an Outbound Shipment🔗

Sometimes, stock sent via an Outbound Shipment will need to be returned. You can do this by creating an Customer Return.

- Open the Outbound Shipment for which you would like to process the return of some or all of the stock

- Make sure that status is at least

SHIPPED - Select the line(s) you want to process the return of by checking the box(es) on the right of the list

- Click the

Return selected linesbutton which appears at the bottom of the page.

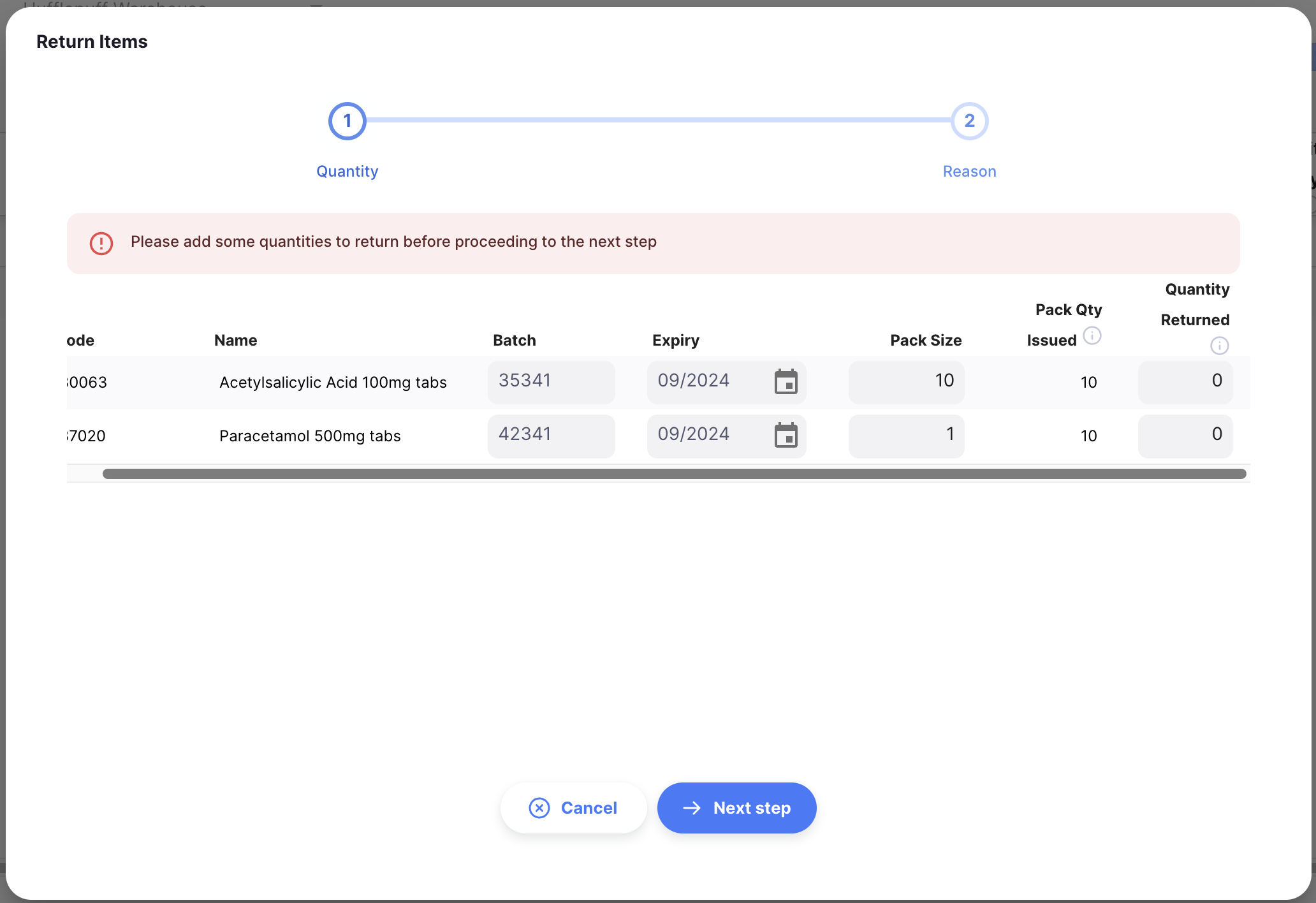

Select quantity returned🔗

A modal will open, containing each line you selected for return:

| Column | Description |

|---|---|

| Code | Item code |

| Name | Item name |

| Batch | Batch number. It is a designation given to products made in the same manufacturing run. |

| Expiry | Expiry date of the batch (format: MM/YYYY) |

| Pack Size | Quantity of units per pack |

| Pack Qty Issued | Number of packs that were issued in the Outbound Shipment |

| Quantity Returned | Number of packs to be returned |

The Quantity Returned values will initially be 0 - you can adjust this to return some or all of the available stock.

Warnings🔗

If you forget to enter a Quantity Returned for any line and click Next step, you will see this warning message. You'll need to add a quantity returned from at least one line. You can click Cancel if you no longer want to process the return of any of this stock.

Provide reasons🔗

Once you are happy with your returned quantities, you can click Next step. The list of lines will be filtered to only include the lines you provided a return quantity for. In this view, you can enter a reason for the return of each line, and an additional comment.

Confirm🔗

When you are happy with the quantities and reasons, you can press on:

- the

OKbutton. a Customer Return will be created, and you will be redirected to view it. - the

Backbutton, to go back to theSelect quantitystep

Viewing an Outbound Shipment🔗

When viewing a specific shipment, you can view the batches on that shipment grouped by item or with each batch listed separately.

To change the view mode, click the Group by item switch.

When grouped by item, you can expand the item to see individual batches, or use the expand in the table header to expand all grouped rows. If you click on an item you will also see all selected batches, as shown in this example:

If you do not have enough room on your screen, or simply aren't interested in some of the columns shown, you have the option of hiding which columns are shown in this view.

Click on the Show / hide columns button which is at the top right of the table. This gives a list of the columns available - you can check the columns you want to see. The options chosen are stored for the current browser, so next time you view an Outbound Shipment, you will see the selected columns only. If you have chosen which columns to show, then the button is shown in blue to remind you that there are more columns available.

View or Edit the Requisition Information Panel🔗

The information Panel allows you to see or edit information about the outbound shipment. It is divided into five sections:

- Additional Info

- Related documents

- Invoice Details

- Transport Details

- Actions

Additional Info🔗

In the Additional Info section you can:

- See who created the Outbound shipment (name of the user)

- See when the Outbound shipment was created

- View and edit the Outbound shipment colour. To edit the colour, tap on the coloured circle and select a colour from the pop-up

- Write or edit a comment

Related Documents🔗

In the Related Documents section you can see other related transactions for the Outbound shipment.

If you the shipment was created from a Requisition you will see the Requisition number and a link to view the Requisition.

Invoice Details🔗

This section lists the service changes, sell price, total price and foreign currency if applicable.

Transport Details🔗

The Transport Details section is where you can enter the expected delivery date and a reference for the delivery.

Actions🔗

- You can tap on the Copy to Clipboard button to copy the Requisition details to the clipboard.

- You can Delete the Outbound shipment if it is not in the

Verifiedstatus.